UHMWPE is one of the world's three high-tech fibers (carbon fiber, aramid and ultra-high molecular weight polyethylene fiber) and the toughest fiber in the world. It is "light and thin like paper, hard as steel" and 15 times stronger than steel.

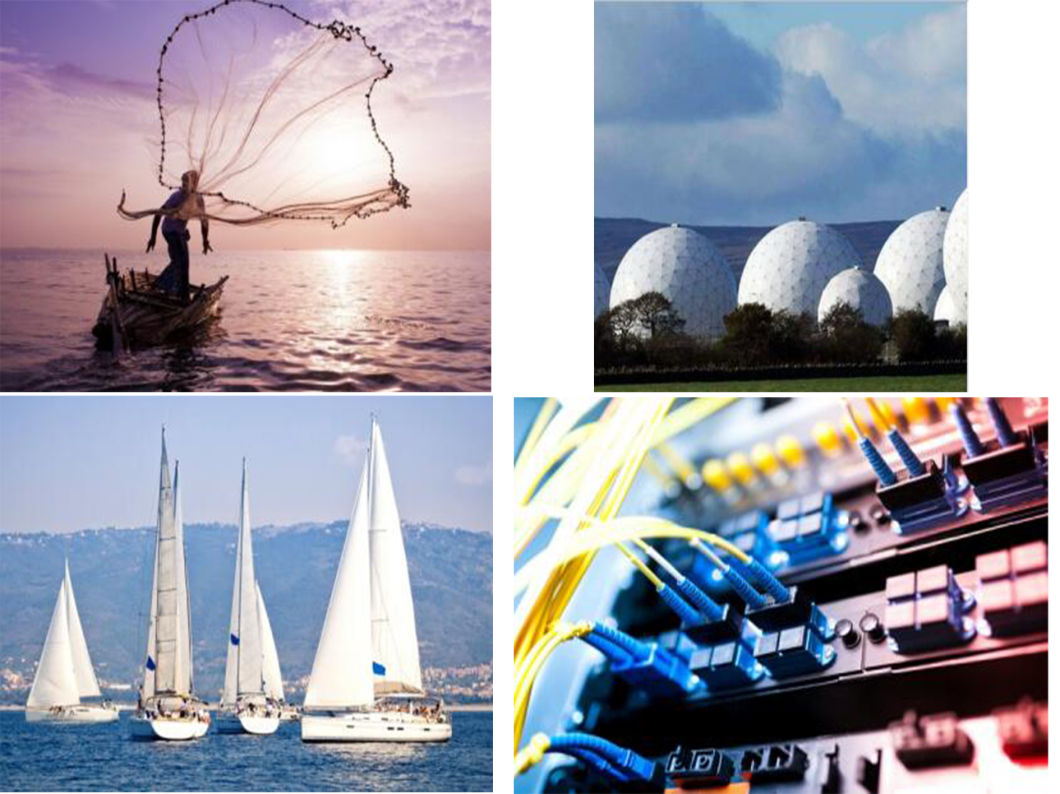

It was widely used in The United States, Europe, Japan and many other countriesin weapons research and development, aerospace, navigation, electronics, weapons, shipbuilding, building materials, sports, medical and many other fields, and its superior performance has been fully reflected.

ADVANTAGES:

- Durability, UHMWPE products'life is 12 times than that of normal nylon polyester.

- Applicability, UHMWPE ropes can be used for a long time at ultra-low temperature (-200 degrees Celsius) and in acid-alkaline seawater. It can also weather tropical rainforest's harsh environment for a long time.

- Superior tensile strength, ultra-low elongation, its strength is 15 times than that of the same modulus steel wire, 40% higher than aramid, and its elongation rate is 3.5%.

- It's wear and cut resistance, better protect you from personal harm.

SPECIAL PERFORMANCE:

- High specific strength, high specific modulus. The specific strength is more than ten times that of the same section of steel wire, and the specific modulus is second only to the special grade carbon fiber.

- Low density of 0.97-0.98g/cm3, it can float on water surface.

- The elongation at break is low, the work of breaking is large, and the ability to absorb energy is strong, so that it has outstanding impact resistance and cut resistance.

- Anti-ultraviolet radiation, anti-neutron and gamma-ray, high specific energy absorption, low dielectric constant, high electromagnetic wave transmittance.

- Chemical resistance, wear resistance, and long flex life.

PHYSICAL PROPERTIES:

- Density:Low density of 0.97-0.98g/cm3, lighter than water, can float on water surface.

- Strength:2.8~4N/tex

- Modulus:91~140N/tex

- Elongation:3.5%~3.7

- Its impact absorption energy is nearly twice as high as that of the PARA-aramid fiber, and the wear resistance is good, and the friction coefficient is small, but the melting point is only 145-160ºC under stress.

| Model | Dtex | Filament | Strenth | Modulus | Elongation | ||||

| cN/dtex | g/den | GPa | cN/dtex | g/den | GPa | % | |||

| J97 | 22 | 10 | 38 | 42.9 | 3.8 | 1800 | 2034 | 180 | 3.5 |

| J97 | 55 | 20 | 36 | 40.7 | 3.6 | 1500 | 1695 | 150 | 3.5 |

| J97 | 110 | 40 | 36 | 40.7 | 3.6 | 1300 | 1469 | 130 | 3.5 |

| J97 | 220 | 120 | 35 | 39.6 | 3.5 | 1250 | 1413 | 125 | 3.5 |

| J97 | 200 | 35 | 39.6 | 3.5 | 1300 | 1469 | 130 | 3.5 | |

| J98 | 440 | 240 | 32 | 36.2 | 3.2 | 1200 | 1356 | 120 | 3.5 |

| 320 | 32 | 36.2 | 3.2 | 1250 | 1413 | 125 | 3.5 | ||

| J200 | 880 | 240 | 38 | 42.9 | 3.8 | 1450 | 1639 | 145 | 3.5 |

| J300 | 880 | 320 | 40 | 45.2 | 4 | 1550 | 1752 | 155 | 3.5 |

| J99 | 1760 | 240 | 33 | 37.3 | 3.3 | 1250 | 1413 | 125 | 3.5 |

| J200 | 1760 | 480 | 35 | 39.6 | 3.5 | 1300 | 1469 | 130 | 3.5 |

| J99 | 3550 | 480 | 30 | 33.9 | 3 | 1100 | 1243 | 110 | 3.5 |

| Z5 | 440 | 120 | 20 | 22.6 | 2 | 1000 | 1130 | 100 | 3.5 |

| Z16 | 440 | 120 | 20 | 22.6 | 2 | 950 | 1074 | 95 | 3.5 |

| ZT 50 | 440 | 120 | 20 | 22.6 | 2 | 900 | 1017 | 90 | 3.5 |

| J92 | 440 | 120 | 20 | 22.6 | 2 | 800 | 904 | 80 | 3.5 |

MAIN APPLICATIONS:

COMPANY PROFILE:

Nantong VANWARD Chemical Co., Ltd. is a trading company specializing in new material products. Relying on the manufacturing base with strong financial strength and technical strength, we've been providing domestic and foreign clients with Ultra-high Molecular Weight Polyethylene (UHMWPE) fiber, covered yarn, UD fabric and other related products which are widely used in variety of industries such as leisure sports, navigation, textile, military, defense, and protective equipments. Our manufacturing base is equipped with internationally advanced R & D, QC and manufacturing facility and implements ISO9001, ISO14001 and OHSAS18001 standards. We have been known as the UHMWPE domestic leader attributed to the best quality and the largest scale with an annual output of 12,000 tons.